TIM - Thermal Interface Material

We have successfully created a wide range of Thermal Interface Materials (TIMs) specifically designed to meet the needs of various electronic applications. These materials are classified into two main categories, based on whether they need dielectric capacity or not. Furthermore, we have developed a comprehensive lineup of TIMs with distinct surface properties, differentiating them based on their self-adhesive nature.

-

Thermal Pad

Acrylic pads offer several advantages, including high thermal conductivity, excellent electrical insulation, and resistance to chemicals, moisture, and UV radiation. They are flexible, conformable, and can be easily cut to size, making them ideal for a wide range of applications such as thermal management, electronic insulation, and gasketing.

See More -

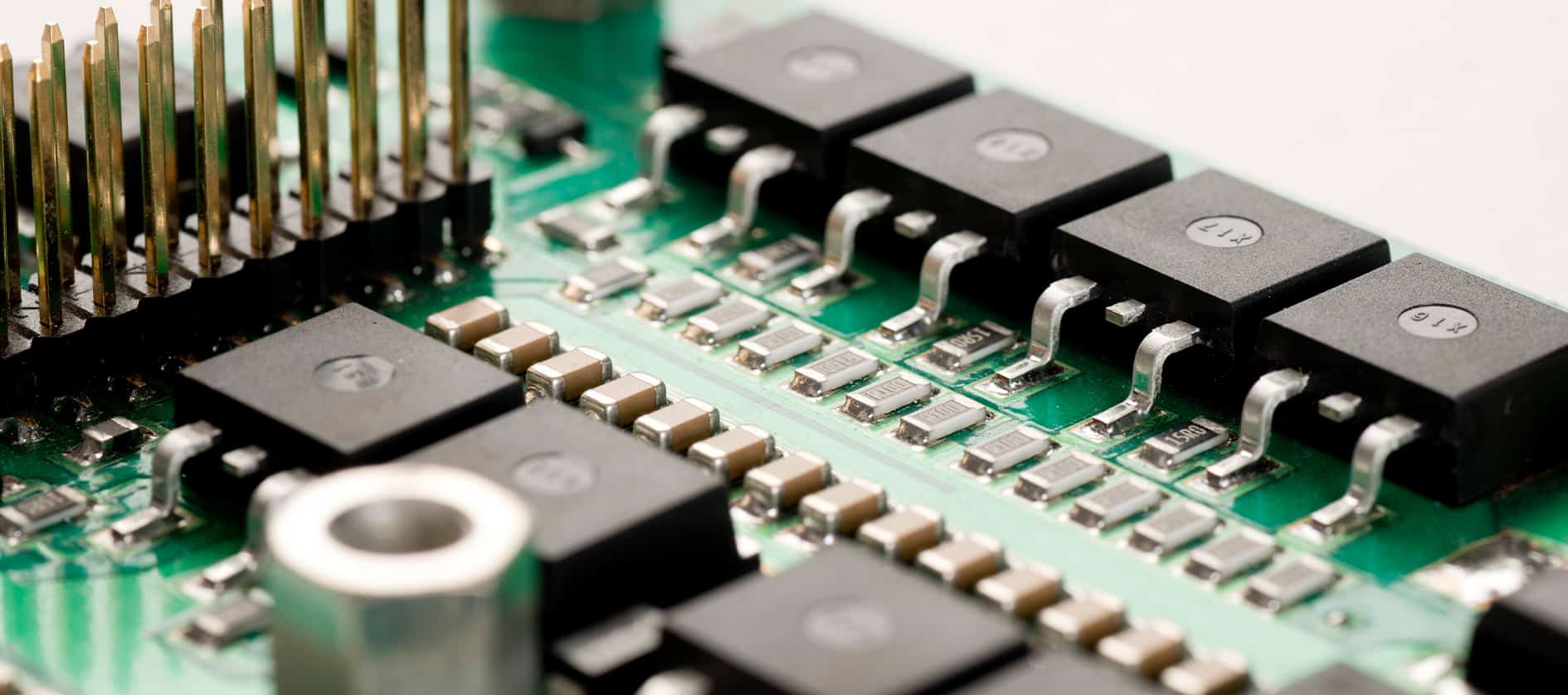

Bond Sheet Cured

BOND SHEET CURED is a reinforced dielectric polymerized interface material designed for high dielectric isolation and low thermal resistance. Ultra-thin dielectric layer with high dielectric strength, high thermal conductivity and low thermal resistance, which efficiently dissipates the heat generated by the power components to the cooling elements. Consisting of a glass fabric base, enriched with mineral fillers. Silicon free. Ideal for pick and place automation.

See More -

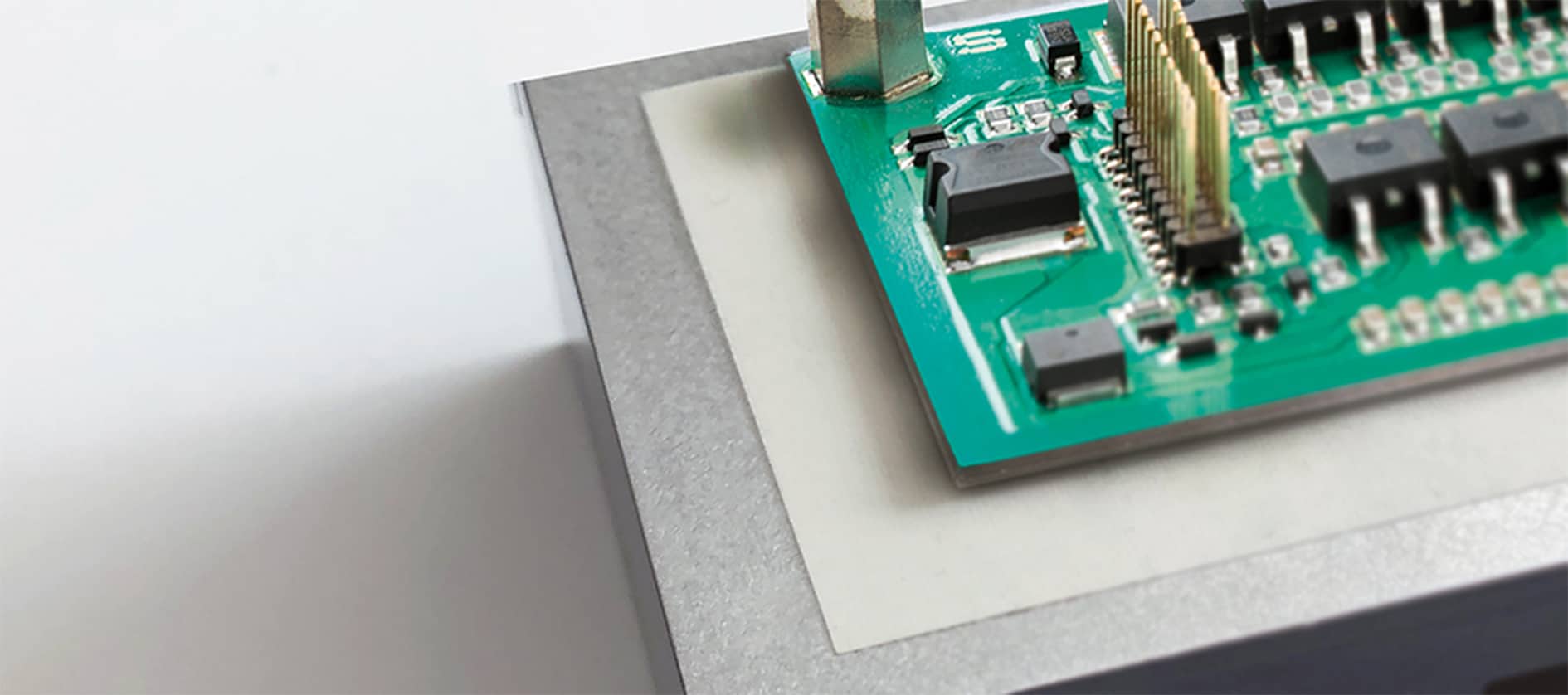

Copperfiller

COPPERFILLER is a TIM developed by Aismalibar designed to eliminate the need to apply thermal paste on the surfaces to be dissipated. It is composed of three layers, the two external ones are responsible for filling the air cavities between the radiators and the components, eliminating the need for thermal paste and a central layer of 30 micron copper designed to distribute the temperature more efficient both in Z axis and in X, Y.

See More -

Thermal Tape & Adhesive

Adhesive film with two-sided adhesive combined with thermal transmission properties based on acrylic resin, PSA (pressure sensitive adhesive). Dual cure technology ensures greater adhesion over time after application. It is ideal to improve the wetting between rough surfaces allowing the conformation of the surface ensuring a good anchoring and excellent thermal transmission.

See More -

Phase Change

Phase change materials (PCMs) have several advantages, including high energy storage density, low volume change during phase transition, and the ability to maintain a constant temperature during thermal energy storage and release. They can also reduce energy consumption and costs in buildings and industrial applications, and can be integrated into existing systems with minimal modifications.

See More -

Thermal Gel

Thermal gels are highly efficient at transferring heat between components, providing excellent thermal conductivity and reducing thermal resistance. They can conform to irregular shapes and surfaces, filling gaps and minimizing air pockets, which improves heat transfer and reduces the risk of overheating.

See More -

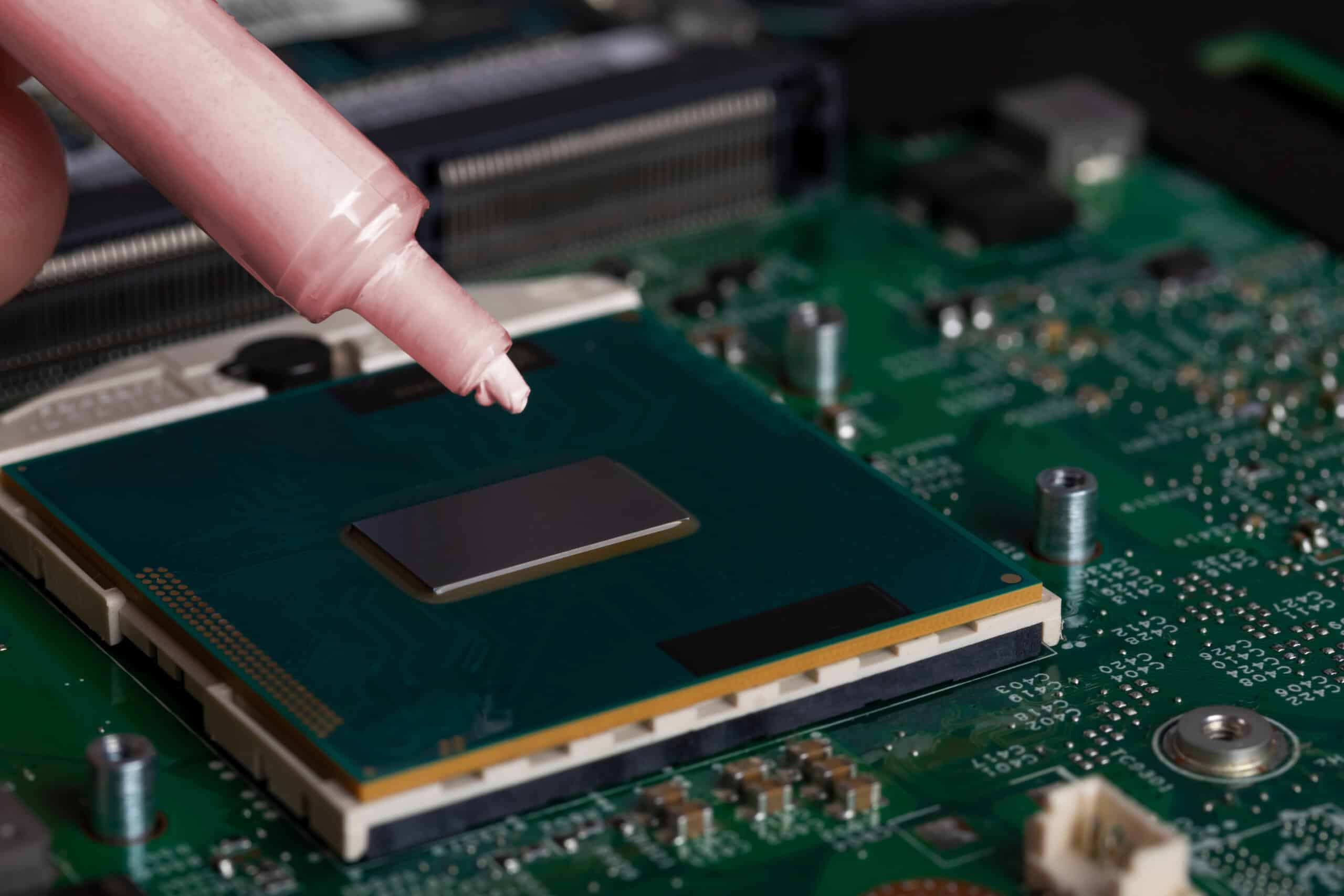

Thermal Grease

Thermal grease, also known as thermal compound, offers several advantages, including high thermal conductivity, low thermal resistance, and excellent heat transfer properties. It fills gaps and irregularities between components, reducing the risk of overheating and improving the overall performance and lifespan of electronic devices. Thermal grease is easy to apply and remove, making it ideal for testing and prototyping. It is also non-toxic and non-corrosive, making it safe for use in sensitive applications such as medical devices.

See More -

Silicone Pads

Silicone pads offer several advantages, including excellent thermal conductivity, electrical insulation, and resistance to high temperatures and harsh chemicals. They are flexible, conformable, and can be easily cut to size, making them ideal for a wide range of applications such as thermal management, electronic insulation, and gasketing.

See More -

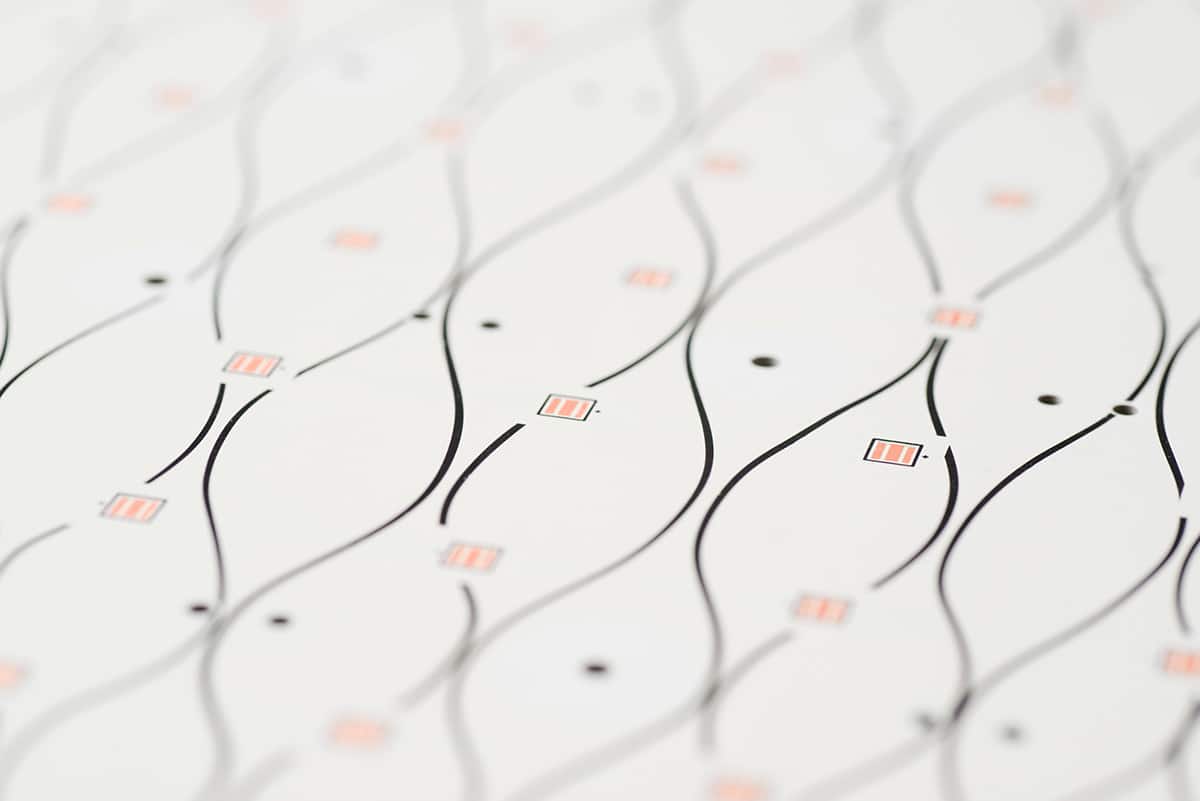

ISOLCOPPER

ISOLCOPPER is a thin copper (35 micron) cladded with an ultrathin dielectric layer filled with high end mineral content. This Aismalibar copper isolated treatment technology reduces the thermal resistance to very low values and achieving a dielectric strength up to 2 kV. CTE expansion XY 17 ppm. Low mounting pressure. Silicon free. No need of thermal grease.

See More