FR4 Thermal properties to consider when designing PCBs

Last modification:

FR4 Thermal properties to consider when designing PCBs

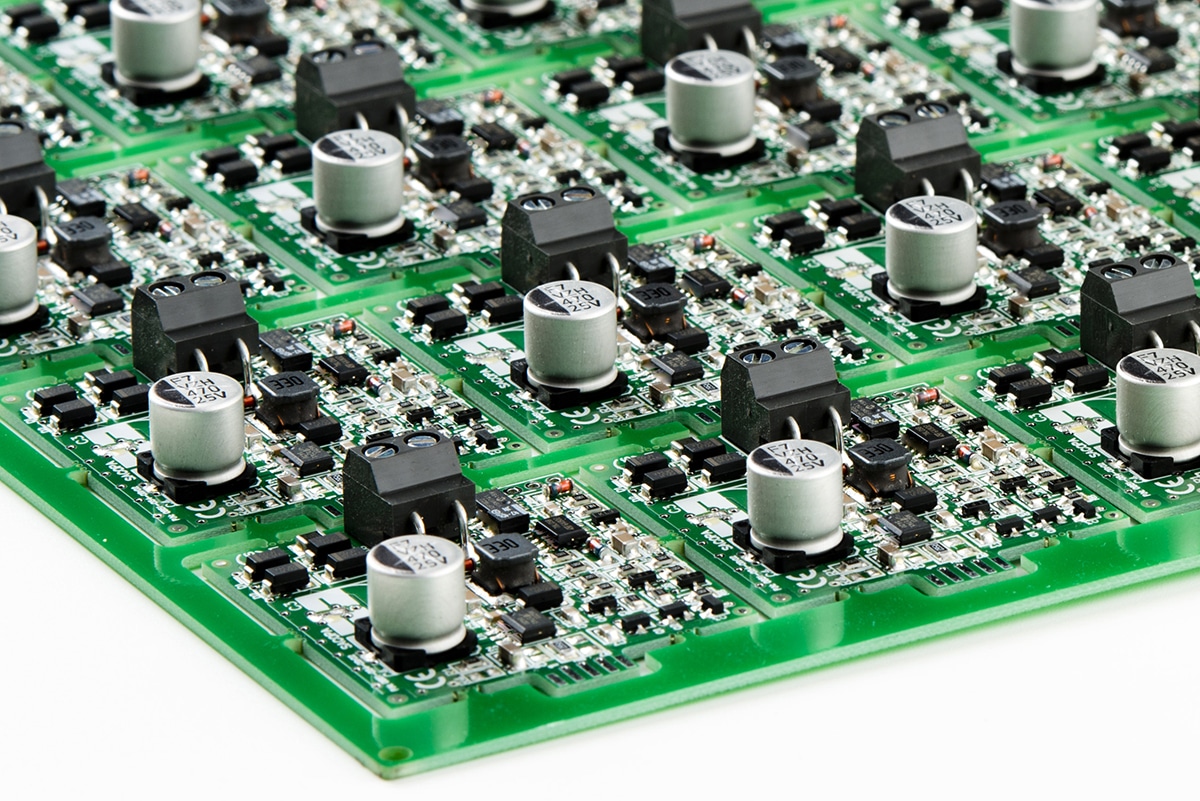

When designing PCBs, designers need to consider four very important thermal properties of the FR4 they have chosen to incorporate.

In this article, we discuss these crucial properties and explain how Aismalibar's thermal FR4 responds to them.

Standard FR4 Thermal properties

The electrical, mechanical, and thermal properties of FR4 grade materials depend on the resin content, glass weave style, glass weave thickness, and type of raw materials used to build up an FR4 substrate.

These materials define the thermal specifications of the FR4, better to say the grade of its Thermal Conductivity, Coefficient of thermal Expansion (CTE), Glass Transition Temperature (Tg) and Minimum/Maximum Operating Temperature (MOT).

1. Thermal Conductivity

Thermal conductivity defines the rate at which heat will move from hot to cold regions in the system. The thermal conductivity rate is a crucial parameter to consider when designing a PCB because this defines the material ability to conduct the heat. Which is the main purpose of a PCB designer job.

Standard FR4 has a thermal conductivity of maximum 0.3 W/mK while Aismalibar Thermal FR4 has a thermal conductivity of 2.2 W/mK and 3.2 W/mk (depending on the product).

2. Coefficient of thermal Expansion (CTE)

CTE measures the rate at which the board will expand along different directions. When materials, which are in contact, expand at different rates, one of them gets stress inducted and this can lead to fatigue and eventually fracture.

Thermal FR4 3,2w

Coefficient of Thermal Expansion before Tg Z 37ppm/ºC

Coefficient of Thermal Expansion after Tg Z 172ppm/ºC

Coefficient of Thermal Expansion 50-250ºC 77ppm/ºC (1.8%)

3. Glass Transition (Tg)

Tg is the reversible transition in amorphous materials from a hard and relatively brittle state into a molten or rubber-like state.

Aismalibar Thermal FR4 with a thermal conductivity of 3.2 W/mk has a high Tg.(180 ºC)

4. Minimum/Maximum Operating Temperature (MOT)

The temperature range at which an electrical or mechanical device operates effectively, based on the device function and application context. This range is defined between the minimum and the maximum operating temperature (known as MOT) of a device.

Outside this range of what is called “safe operating temperature”, the proper functionality of the device may be negatively affected.

Aismalibar Thermal FR4’s MOT is 150 ºC

A further consideration

Last but not least, when designing PCBs, Aismalibar R&D engineers also consider another important thermal properties of the FR4: the thickness of the copper.